Welding Processes Handbook

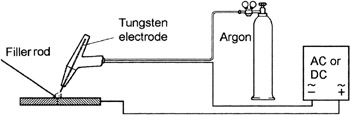

TIG welding (also called Gas Tungsten Arc Welding, GTAW) involves striking an arc between a non-consumable tungsten electrode and the workpiece. The weld pool and the electrode are protected by an inert gas, usually argon, supplied through a gas cup at the end of the welding gun, in which the electrode is centrally positioned.

TIG welding can also be used for welding with filler material, which is applied in rod form by hand similar to gas welding. Tools for mechanised TIG welding are used for applications such as joining pipes and welding tubes into the end plates of heat exchangers. Such automatic welding tools can incorporate many advanced features, including mechanised supply of filler wire.

Characteristics of the method include:

the stable arc

excellent control of the welding result.

The main application for TIG welding is welding of stainless steel, welding of light metals, such as aluminium and magnesium alloys, and the welding of copper. It is also suitable for welding all weldable materials, apart from lead and zinc, with all types of joints and in all welding positions. However, TIG welding is best suited to thin materials, from about 0.5 mm up to about 3 mm thick. In terms of productivity, TIG welding cannot compete with methods such as short arc welding.

The following equipment is required for TIG welding:

welding gun

HF (= high-frequency) generator for ignition of the arc

a power...