About

Founded in 1976.

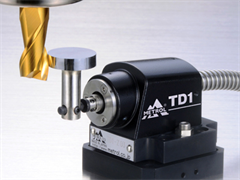

METROL specializes in manufacturing Ultra Precision Switches.

METROL has developed "precision mechanical switches/sensors," while most industrial switches/sensors were electrical.

This was unlike any other in the world.

Our switches were co-invented with TOYOTA for realizing stable positioning under harsh working conditions like automotive manufacturing lines where coolant and cutting chips splatter.

We also own more than 50 patents both inside and outside Japan for their originality. In machine tool industry, METROL tool setters are widely used by more than 70 machine tool builders in 17 countries.

We have been dedicated to contribute manufacturers by improving machine accuracy and reducing costs.

Our products are now used in not only long standing automobile industry and machine tool industry but also in leading companies in semiconductor, robot, medical equipment and smartphone industries.

Our products are now used in not only long standing automobile industry and machine tool industry but also in leading companies in semiconductor, robot, medical equipment and smartphone industries.

Our unique and distinct product development is supporting manufacturing across the world.

? METROL Head office in Tokyo