Manual of Gear Design: Helical and Spiral Gears, Volume III

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

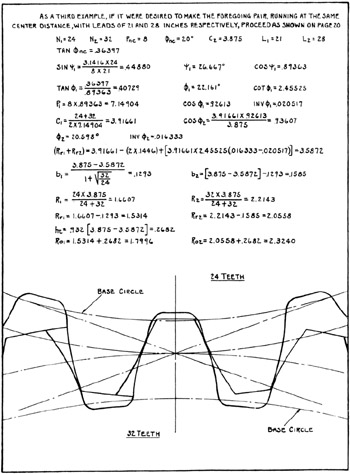

WHEN PINIONS WITH SMALL NUMBERS OF TEETH ARE REQUIRED, IT IS NECESSARY TO ENLARGE THEIR DIAMETER TO AVOID EXCESSIVE UNDERCUTTING. THE FOLLOWING EQUATIONS APPLY TO PAIRS OF HELICAL GEARS WHEN THE DRIVING PINION HAS FROM 5 TO 16 TEETH.

WHEN,

N 1 = NUMBER OF TEETH IN PINION

N 2 = NUMBER OF TEETH IN GEAR

C = CENTER DISTANCE

P n = NORMAL DIAMETRAL PITCH

= CIRCULAR PITCH IN PLANE OF ROTATION

? = HELIX ANGLE AT PITCH LINE

R 1 = PITCH RADIUS OF PINION

R 2 = PITCH RADIUS OF GEAR

R o1 = OUTSIDE RADIUS OF PINION

R o2 = OUTSIDE RADIUS OF GEAR

R r1 = ROOT RADIUS OF PINION.

R r2 = ROOT RADIUS OF GEAR

T 1 = ARC TOOTH THICKNESS OF PINION IN PLANE OF ROTATION AT R 1

T 2 = ARC TOOTH THICKNESS...