About

Smart Solutions on the Cutting Edge

Demand on production for small parts around the world is continuously increasing. Higher expectations are put on the producers of these parts, and this is where WhizCut comes in.

At WhizCut they understand the day to day challenges the users of automatic lathes are up against. To assist these users WhizCut has developed a wide range of useful products for all automatic lathes around the globe.

WhizCut tries, to put it simply, to find new solutions for existing problems within the world of small part machining. Their company is based on these new products that will make your production faster, more precise and more effective. No matter if your work is in external cutting or internal cutting, WhizCut has the solutions to boost your production.

WhizCut is determined to continue being one of the leading manufacturers for small part machining in the world.

Tooling for CNC Swiss Automatic Lathes

Tooling for CNC Swiss Automatic Lathes

WhizCut offers a complete external and internal range of tool holders and carbide inserts specially developed for CNC Swiss type automatic lathes. With this new precision tooling, WhizCut will help you improve productivity and reduce interruptions in production in your Swiss lathe.

WhizFix Tool holder System

WhizFix Tool holder System

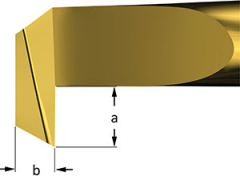

The WhizFix tool holder system for external turning in Swiss automatics uses a bent pin and a nut to index the insert. Indexing an insert is easy, accurate and quick. You can index or change the insert while the tool holder is in the machine, even if there only is access from the back side of the tool holder.

WhizIn Internal Cutting System

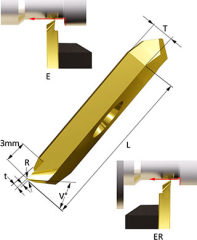

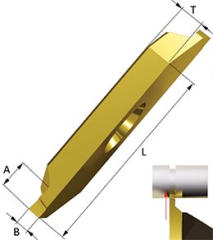

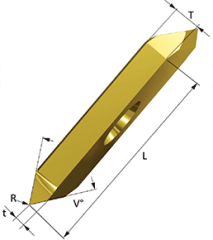

The WhizIn tool holder for internal turning in Swiss automatics has the carbide boring bar mounted at an angle to achieve greater precision. By mounting the carbide boring bar at an angle they grind away less from the base of the insert which makes the boring bar more stable. Other benefits are less grinding time and grinding stress, and that the coolant may go through the tool holder and spray directly on to the cutting zone.

The WhizIn tool holder for internal turning in Swiss automatics has the carbide boring bar mounted at an angle to achieve greater precision. By mounting the carbide boring bar at an angle they grind away less from the base of the insert which makes the boring bar more stable. Other benefits are less grinding time and grinding stress, and that the coolant may go through the tool holder and spray directly on to the cutting zone.

WhizThrill Solid Carbide Thread Mills

WhizThrill Solid Carbide Thread Mills

WhizCut will change the way thread mills are used today by introducing WhizThrill. The WhizThrill deburring solid carbide thread mills take thread milling to the next level.

WhizThrill thread mills are produced with the best carbide and coating combination to be in forefront of technology both when it comes to tool design and material. WhizCut also offers a wide range of micro thread mills with extra tool strength.

WhizCut Special features

|

|