Vacuum Technology: Calculations in Chemistry

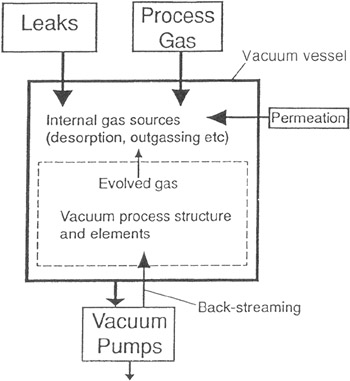

It is impossible to eliminate all sources of gas in vacuum systems. Even in the best-designed and operated static systems at very low pressure, small leaks are present and slight outgassing occurs, and the resulting gas load has to be dealt with by the system's pumps. The usual sources of gas are indicated in Figure 4.1, and some general comments should be made before more detailed discussion in later sections.

Leaks. No system can be free of leaks but leakage must be reduced to the extent that it no longer adversely affects the performance of the vacuum system.

Outgassing. Any material that has been exposed to gas, particularly atmospheric air, will adsorb or otherwise entrap that gas. Under reduced pressure, not only do the inner walls and associated components contribute to the gas load but also any substrates or material being processed.

Permeation. The metals and alloys normally used in vacuum systems can be regarded as impermeable to air even at high temperatures. In some circumstances, however, the permeation of H 2, He, O 2, air, etc. through elastomers, glasses and some metals must be considered.

Process gas. In, for example, flow-reactors, sputtering systems and systems with flowing purge gas, gas is deliberately introduced. In such cases, the pumping system must deal with this gas load, in addition to 1 3 above, to maintain the pressure.

A leak is a flow path in...