Engine Starters Information

Description

Engine starters provide the initial rotation for internal combustion engines. They cause the pistons to move before ignition, enabling the engine to turn over so that it can then operate under its own power.

Engine starters are available for engines of all sizes, and include products other than just electric motors.

Applications

Engine starters are used in many applications including:

-

Gasoline, marine, and diesel engines

-

Portable generators

-

Mining equipment

-

Construction equipment

-

Irrigation pumps

-

Turbines

-

Jet engines

-

Aircraft

Types

Engine starter types include pneumatic, hydraulic, electric, spring, manual, and recoil.

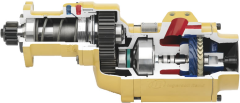

Pneumatic

Pneumatic engine starters or air starters are used to start diesel engines, gas turbines, and some reciprocating engines. They provide rapid acceleration and high turning speeds for immediate ignition. Compared to electric starters, air starters and air start systems have a higher power-to-weight ratio. Typically, they admit compressed air or gas to cylinders whose pistons are just over top dead center, forcing them downward.

Specifications for pneumatic air starters include:

-

Maximum working pressure

-

Maximum power

-

Speed at maximum power

-

Maximum torque

-

Net weight

-

Maximum diameter of the air feed piping

Hydraulic

Hydraulic engine starters are used in field generators, marine propulsion engines, water pumping equipment for fire suppression, and hydraulic fracturing (fracking) equipment for oil and gas exploration. They are also used in diesel engines, typically those with 6 to 16 cylinders that require emergency starts over a range of temperatures.

Like pneumatic engine starters and other air starting systems, hydraulic engines starters are designed for spark-less operation. Related components include valves, pumps, filters, reservoirs, and piston accumulators.

Product specifications for hydraulic engine starters include pressure range and crank size.

Electric

Electric engine starters use either a permanent magnet or a direct current (DC) electric motor with a starter solenoid. They are often used in cars, trucks, boats, and construction equipment. When a key-operated switch is activated, current from a battery is applied to the solenoid. The solenoid then engages a lever that activates the driveshaft, pushing a drive pinion until it meshes with the starter ring gear on the engine’s flywheel. Once the engine starts, a spring separates the pinion gear from the ring gear, causing the starter motor to stop.

Specifications for electric engine starters include parameters for connecting and switching.

Spring

Spring starters are mechanical devices that do not require electricity, hydraulic pressure, or compressed air. Energy is store in a manually-rechargeable power spring or spring pack that eliminates the need for a battery, alternator, or wiring. In some systems, a conversion kit can be installed to provide electrical power.

Typically, spring starters are used in industrial, marine and agricultural applications; often in remote or hazardous locations.

Manual and Recoil

Manual engine starters and recoil engine starters are used in lawnmowers, snow blowers, motorcycles, and other small engines.

Standards

A-A-59294 - Starters, engine, electrical

MIL-S-22999 - Starters, aircraft engine, hydraulic

MIL-S-27266 - Starter, engine, cartridge/pneumatic shaft drive

References

Image Credit:

Ingersoll Rand Industrial Technologies / Air Motors