Plasticity in Reinforced Concrete

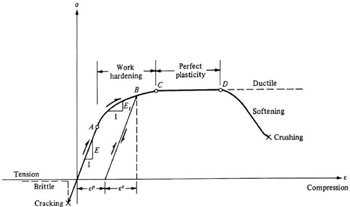

Figure 6.1 shows a typical uniaxial stress-strain curve for plain concrete up to tensile and compressive failure. For tensile failure, the behavior is essentially linearly elastic up to the failure load, the maximum stresses coincide with the maximum strains, and no plastic strains occur at the failure moment. For compressive failure, the material initially exhibits almost linear behavior up to the proportional limit at point A, after which the material is progressively weakened by internal microcracking up to the end of the perfectly plastic flow region CD at point D. The nonlinear deformations are basically plastic, since upon unloading only the portion ? c can be recovered from the total deformation ?. It is clear that the phenomenon in the region AC and in the region CD corresponds exactly to the behavior of a work-hardening elastoplastic and elastic perfectly plastic solid, respectively. As can be seen from Fig. 6.1, the total strain ? in a plastic material can be considered as the sum of the reversible elastic strain ? c and the permanent plastic strain ? p. A material is called perfectly plastic or work-hardening according as it does or does not admit changes of permanent strain under constant stress.

For moderate strains, mild steel behaves approximately like a perfectly plastic material. In view of the importance of mild steel as the reinforcing material in reinforced concrete,...