Products & Services

See also: Categories | Featured Products | Technical Articles | More Information-

Supplier: Columbia Steel Casting Co., Inc.

Description: Grinding balls and more In addition to quality high chromium alloy iron balls, Columbia is interested in producing any wear or structural parts our customers need. Our product engineers are available to work closely with you to improve replacement parts. Top and

- Industry & Application: Crushers & Grinding Mills

-

Supplier: High Performance Alloys, Inc.

Description: Corrosion and abrasion resistant, tough and durable, NITRONIC 30 is the stainless steel for your abrasive needs. Ball mill tests have shown that many application standards, such as AR 500 suffer six to seven times as much metal loss as NITRONIC 30. Economical, low alloy, corrosion

- Corrosion Resistant: Yes

- Function & Thickness: Abrasion / Sliding Wear

- Industry & Application: Automotive / Transportation, Chemical Process

- Material: Metal

-

Supplier: High Performance Alloys, Inc.

Description: Corrosion and abrasion resistant, tough and durable, NITRONIC 30 is the stainless steel for your abrasive needs. Ball mill tests have shown that many application standards, such as AR 500 suffer six to seven times as much metal loss as NITRONIC 30. Economical, low alloy, corrosion

- Applications: Abrasive / Erosive Wear Protection, Automotive / Vehicular, Chemical / Materials Processing, Marine, Wear Parts / Tooling

- Elongation: 35 %

- Performance Features: Corrosion Resistant, Wear Resistant

- Processing Features: Wrought, Forged

-

-

Supplier: FLSmidth

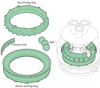

Description: Availability Designed to save and destined to succeed, the new 3-piece screw has made the Fuller-Kinyon Type M Pump better than ever. Replacement or removal of parts - and lower plant maintenance costs - have never been easier. Specialties Maximum material temperature for standard Type

Find Suppliers by Category Top

Featured Products Top

-

Processing, Compressed Air Services, Condensate Removal, Coolants, Effluent Lines, Degreasing, Pickling, Plating, Washdown, Demineralizers, Dewatering and Sludge Movement, Filtration Systems, Hydraulic/Pneumatic Systems and Lifts, Ink Spraying and Cleaning, Line Purge, Machine Cooling, Mixing, Filling, Material Flow, Municipal Service, Natural Gas and Oil Production, Solid and Liquid Waste Control, Steel Mills, General Chemical Application. (read more)

Processing, Compressed Air Services, Condensate Removal, Coolants, Effluent Lines, Degreasing, Pickling, Plating, Washdown, Demineralizers, Dewatering and Sludge Movement, Filtration Systems, Hydraulic/Pneumatic Systems and Lifts, Ink Spraying and Cleaning, Line Purge, Machine Cooling, Mixing, Filling, Material Flow, Municipal Service, Natural Gas and Oil Production, Solid and Liquid Waste Control, Steel Mills, General Chemical Application. (read more)

Browse Pneumatic Valve Actuators Datasheets for DynaQuip Controls -

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro (read more)

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro (read more)

Browse Zirconium Oxide and Zirconia Ceramics Datasheets for Xiamen Innovacera Advanced Materials Co., Ltd. -

The Vaughan Cantilever Pump is the toughest design available for waste sumps with high solids, abrasives or corrosives content. Applications include fish waste, pulp and paper recycling, mining, storm drains and mill scale. Eliminates submerged seals and bearings Best for (read more)

The Vaughan Cantilever Pump is the toughest design available for waste sumps with high solids, abrasives or corrosives content. Applications include fish waste, pulp and paper recycling, mining, storm drains and mill scale. Eliminates submerged seals and bearings Best for (read more)

Browse Datasheets for Vaughan Co., Inc. -

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Browse Gears Datasheets for Chengdu Leno Machinery Co., Ltd. -

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Browse Spur Gears Datasheets for Chengdu Leno Machinery Co., Ltd. -

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Browse Spur Gears Datasheets for Chengdu Leno Machinery Co., Ltd. -

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Browse Spur Gears Datasheets for Chengdu Leno Machinery Co., Ltd. -

Corrosion and abrasion resistant, tough and durable, NITRONIC® 30 is the stainless steel for your abrasive needs. Ball mill tests have shown that many application standards, such as AR 500 suffer six (read more)

Corrosion and abrasion resistant, tough and durable, NITRONIC® 30 is the stainless steel for your abrasive needs. Ball mill tests have shown that many application standards, such as AR 500 suffer six (read more)

Browse Carbon Steels and Alloy Steels Datasheets for High Performance Alloys, Inc. -

The preparation of ceramic hip joints mainly includes: powder preparation, forming, green body processing, debinding, sintering, densification treatment, tempering, internal grinding, ball milling, external grinding, ultrasonic cleaning, annealing of semi-finished products, marking (read more)

The preparation of ceramic hip joints mainly includes: powder preparation, forming, green body processing, debinding, sintering, densification treatment, tempering, internal grinding, ball milling, external grinding, ultrasonic cleaning, annealing of semi-finished products, marking (read more)

Browse Specialty Ceramics Datasheets for Suntech Applied Materials (Hefei) Co.,Ltd -

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Spur gears are generally seen as best for applications that require speed reduction and torque multiplication, such as ball mills and crushing equipment, or Examples of high-speed applications that use spur gears – despite their high noise levels – include consumer appliances such as (read more)

Browse Gears Datasheets for Chengdu Leno Machinery Co., Ltd.

Conduct Research Top

-

Speed-up Your Synthesis Lab: Planetary Ball Mills As A Tool In Organic Synthesis

The Institute for Technical Chemistry and Environmental Chemistry of the Friedrich-Schiller University of Jena has developed new and improved methods for synthesis strategies using Planetary Mills in the organic synthesis laboratory - without solvents. Ball Mills are suitable for solvent-free

-

Planetary Ball Mills as an Instrument in Mechanochemistry

One of the most significant fields of application for FRITSCH Planetary Mills is mechanochemistry. This subject is in theory, as well as in practice very wide-ranging and versatile. In the article you will find summarized information about history, functionality and the fields of application

-

Milling of Ductile Materials with Planetary Ball Mills

Comminuting ductile materials such as precious metals can be challenging, but can be mastered with FRITSCH Planetary Mills.

-

High-speed stirred ball mills save mineral supplier money over contract grinding

To save the costs of contract grinding, a mineral supplier install two high-speed Attritors for fine grinding of baryte and calcium carbonate

-

Attritor Grinding and Dispersing Equipment

Overview on particle size reduction, attrition milling technology, and comparison of various types of ball mills

-

Mechanical Alloying

"cold-welding" various metal powders mixtures in a special high energy ball mill

-

Processing Silage for Biogas

New ideas are necessary for the production of renewable energy sources and for the sample preparation a Planetary Ball Mill.

-

Mechanical Alloying: For Frabrication of Advanced Engineering Materials

Mechanical Alloying: For Frabrication of Advanced Engineering Materials. Written to benefit metallurgists unacquainted with ball milling fabrication, this book is a guided introduction to mechanical alloying, covering material requirements equipment, processing and engineering properties

More Information Top

-

Solid-Liquid Separation in the Mining Industry

This mill, see Fig. 1.5, which is much larger than a con- ventional ball mill , Fig. 1.6, can replace part of the crushing circuit, the secondary and tertiary crushing, and the primary grinding, with great success.

-

CERAMIC ABSTRACTS

Ceramics, 5 [57] 415-19 (1953).-B. deals briefly and simply with replacement of parts and repairs to stone breakers, ball mills , bearings, interlocks for ball mills, batch and con- tinuous mills, agitators with silent worm reduction gear, sifters, blungers, filter presses …

-

Economics and methodology of ball mill media maintenance

Today, there are many ball mills of this size still in operation, although as replacement parts for them become almost impossible to obtain, they are being retired more frequently than repaired.

-

New technology of separation of the collective lead-zinc concentrate

The sands of hydrocyclones (one part) is combined with the mill feed ing (four parts) and milled in the diluted pulp with the replacement of the part of balls (8–10%) of healds with coarseness of –100+20 mm.

-

Introduction of Three-Stage Thermal Hardening Technology for Large Diameter Grinding Balls

Recovery and processing in Ukraine of lean iron ores of the Krivoi Rog basin are accompanied by increased wear of replaceable parts of crushing and grinding equipment, including the grinding balls of drum mills .

-

Synthesis of bulk solids processing systems

In handling these materials, use replaceable crushing agents, such as the balls in a ball mill , for equipment parts which are prone to excessive wear.

-

Toughening of yttria-stabilised tetragonal zirconia ceramics

a mechanical components, e.g. seals, thrust bearings, milling media, pump parts ; b orthopaedic implant mate- rial for use as femoral ball heads in total hip joint repla- cement (THR); individual components of THR assembly showing ZrO2 femoral ball head are shown …

-

Materials Processing and Manufacturing III

The liner will be put on the ground through the forklift, and then another new liner will be transported to the ball mill and fixed artificially. Main girder is the key working part of the liner replacement manipulator.

Indicates content that may require registration and/or purchase.

Indicates content that may require registration and/or purchase.