The Science of Ice Cream

The mechanical and rheological properties are measures of how materials respond when they are deformed. Solids are characterized by mechanical properties such as the Young's modulus, strength and hardness, whereas liquids are characterized by rheological properties such as the viscosity and yield stress.

When a stress ( i.e. a force per unit area) is applied to a solid, for example it is stretched, sheared, twisted or squashed, it deforms, i.e. changes its length, or shape. For small deformations, the amount of deformation is proportional to the applied stress. The material is said to behave elastically. Beyond a certain deformation (the elastic limit) the material ceases to be elastic, and the material no longer returns to its initial shape when the stress is removed. This is called plastic deformation. If the material is deformed further then it will eventually break. Some materials, such as rubber, are elastic for large deformations, while others, such as plasticine, have a relatively small elastic limit but can then undergo large plastic deformations. Brittle materials, such as china, can only withstand small deformations before they break.

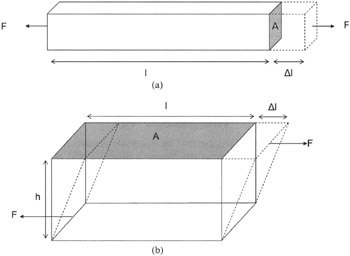

Figure 6.10 shows two ways of deforming a solid. Figure 6.10a shows deformation by stretching. In the elastic region, the fractional change in length (the strain ? l/ l) is proportional to the stress, and the constant of proportionality is the Young's modulus, Y.