Ship Construction, Sixth Edition

The shell plating forms the watertight skin of the ship and at the same time, in merchant ship construction, contributes to the longitudinal strength and resists vertical shear forces. Internal strengthening of the shell plating may be both transverse and longitudinal and is designed to prevent collapse of the plating under the various loads to which it is subject.

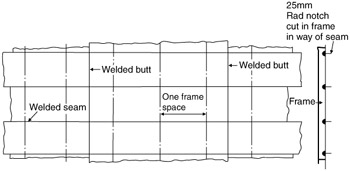

The bottom and side shell plating consists of a series of flat and curved steel plates generally of greater length than breadth butt welded together. The vertical welded joints are referred to as 'butts' and the horizontal welded joints as 'seams' ( see Figure 17.1). Stiffening members both longitudinal and transverse are generally welded to the shell by intermittent fillet welds with a length of continuous weld at the ends of the stiffening member. Continuous welding of stiffening members to the shell is found in the after peak, the bottom shell within the forward 30 per cent of the length and where higher tensile steel is used. Framing is notched in way of welded plate butts and seams.

Throughout the length of the ship the width and thickness of the keel plate remain constant where a flat plate keel is fitted. Its thickness is never less than that of the adjoining bottom plating.

Strakes of bottom plating to the bilges have their greatest thickness over 40 per cent of the ship's length amidships, where the bending stresses are highest. The bottom...