Direct Strip Casting of Metals and Alloys: Processing, Microstructure and Properties

Solidification is the transformation of liquid into the solid crystalline state via the nucleation of the solid phase and its subsequent growth to consume the liquid. The solidification reaction is fundamental to many technological processes such as ingot and foundry casting, continuous slab casting, net-shape die casting, welding and joining and single crystal growth for the production of semiconductor devices and turbine blades. The production of strip products by direct strip casting (DSC) is particularly reliant on a sound fundamental understanding of the atomic processes that govern both the nucleation and growth stages of solidification. The control of these stages dictates the microstructure and many important properties of the as-cast strip. This chapter provides an overview of some of the more important theoretical and practical aspects of solidification phenomena applicable to casting of metals and alloys.

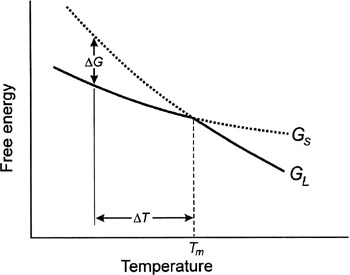

When a liquid is cooled below its equilibrium melting temperature (T m), there is a thermodynamic driving force for solidification ( ?G). Figure 2.1 shows the free energy as a function of temperature for a solid and liquid phase which indicates how the change in free energy ( ?G) varies with respect to T m.

The free energies of both the liquid and solid at a temperature, T, are given by G L = H L TS L and G