Hydraulic Fittings Information

Image Credit: Parker Hannifin | Grainger Industrial Supply | Stucchi, Inc.

Hydraulic fittings are parts used to connect hoses, pipes, and tubes in hydraulic systems. Hydraulic equipment generally operates under high pressures and is often not a fixed system. Consequently, hydraulic fittings need to be strong, versatile, and reliable to operate safely and effectively in their respective applications. These fittings typically adhere to strict standards which dictate fitting construction, dimensions, and pressure ratings.

Hydraulic Pipes, Tubes, and Hoses

It is important to distinguish what type of hydraulic equipment is being connected in the system to determine what fittings are appropriate.

-

Hydraulic tubes are seamless precision pipes specially manufactured for hydraulics. The tubes have standard sizes for different pressure ranges, with standard diameters up to 100 mm. Tubes lengths are interconnected via flanges, welding nipples, flare connections, or by cut-rings. Direct joining of tubes by welding is not acceptable since the interior cannot be inspected.

-

Hydraulic pipes are larger diameter hydraulic tubes. Generally these are used for low pressure applications or when hydraulic tubes are not available. They can be connected by welds or threaded connections. Because of the larger diameters the pipe can usually be inspected internally after welding.

-

Hydraulic hose is graded by pressure, temperature, and fluid compatibility. Hoses are used in applications where pipes or tubes are not suitable, usually to provide flexibility for machine operation or maintenance. The hose consists of multiple layers of rubber and steel wire. Hydraulic hoses generally have steel fittings swaged on the ends. The weakest part of hydraulic hose is the connection of the hose to the fitting, which is why proper fitting selection and installation is essential in high pressure applications.

Types of Fittings

Hydraulic fittings are distinguished based on the connection type and function it performs.

Connection Type

Hydraulic fittings are attached via a number of different connection methods, each with its own conveniences and advantages.

Compression Fittings

Compression fittings include all types of fittings which use compressive force to connect the vessel to the fitting.

-

Standard compression fittings use metal gaskets, rings, or ferrules which form a seal on the vessel through compression. The compression is typically made by tightening a nut onto the fitting over the piping and ferrule, compressing, and securing the vessel inside. Standard compression fittings do not require tools to assemble, making them convenient for quick field installations.

Image Credit: Carr Lane Manufacturing

- Bite-type fittings are compressive fittings with a sharpened ferrule that "bites" the vessel when compressed and provides the seal. Bite-type fittings, like standard compressive fittings, require no special tools to assemble, but provide a stronger, higher pressure connection.

- Mechanical grip fittings are two-ferrule assemblies. The back ferrule grips the vessel while pressing up against the front ferrule, which spring-loads the front ferrule and creates a seal between the piping and fitting body. These fittings can be reassembled multiple times without damaging components or piping. They have good resistance to mechanical vibration.

Image Credit: Valvefittingtube.com

- Flare fittings consist of a body with a flared or coned end. Special flaring tools are used to install the vessel inside the flared end, providing a deep seal. Flare fittings can handle higher pressures and a wider range of operating parameters than standard compression fittings.

Image Credit: Parker Hannifin

Crimp Fittings

Crimp fittings involve placing hose over a tubular end and crimping against it with a sleeve, ring, or crimp socket. These fittings typically require crimping tools or machines to make the connections.

Image Credit: Digital Dezines | Parker Hannifin

End Fittings

End fittings provide specific surfaces for connecting vessels in hydraulic systems.

- Clamp ends are fittings which allow hoses or tubes to be clamped over the part.

-

Plain ends are fittings with surfaces which allow pipes or tubes to be connected by adhesive, solder, welding, or other permanent means. Welding, when done properly on compatible materials, provides a strong and reliable connection.

Flange Fittings

Flange fittings are rims, edges, ribs, or collars with flush surfaces perpendicular to the attached pipe or tube. These surfaces are joined and sealed via clamps, bolts, welding, brazing, and/or threading. For more information on flanges, visit the Pipe Flanges Selection Guide on GlobalSpec.

Image Credit: Main Manufacturing, Inc.

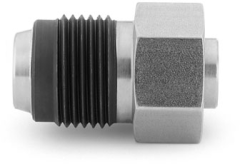

Push-to-Connect

Push-to-connect fittings have ends that are designed to accept tubing by pushing it into the end. These fittings typically disconnect via some type of collar retraction. These connections are convenient for sections of the system requiring frequent disconnection and reconnection.

Image Credit: Parker Hannifin

Threaded Fittings

Threaded fittings have screw threads (built-in grooves) on their inner (female) or outer (male) surfaces designed to accept connections with matching threads. Threads which provide a simple connection but no seal are called straight threads. Tapered threads are designed to provide a tight seal for gases or fluids under pressure. Seal reliability can be improved by adding a coating or seal tape (Teflon). Especially precise threads are called "dry fit", meaning they seal without the need for an additional sealant, which is important in applications where sealant addition could cause contamination or corrosion.

Image Credit: Grainger Industrial Supply

The thread size is measured and based on the inside of the vessel. Thread size standards include NPT (National Pipe Thread) and BSP (British Standard Pipe), though other standards exist and usage often varies by country and industry. Each standard corresponds to a particular number of threads per inch (TPI). Plumbingsupply.com provides an excellent overview on pipe thread sizing. Below is a chart depicting nominal thread sizes and their corresponding values.

|

OD |

OD Actual |

Thread Designation - Nominal Size |

Thread per inch |

|

|

(fraction inch) |

(inches) |

(inches) |

NPT |

BSP |

|

5/16 |

0.3125 |

1/16 |

27 |

28 |

|

13/32 |

0.405 |

1/8 |

27 |

28 |

|

35/64 |

0.540 |

1/4 |

18 |

19 |

|

43/64 |

0.675 |

3/8 |

18 |

19 |

|

27/32 |

0.840 |

1/2 |

14 |

14 |

|

1-3/64 |

1.050 |

3/4 |

14 |

14 |

|

1-5/16 |

1.315 |

1 |

11-1/2 |

11 |

|

1-21/32 |

1.660 |

1-1/4 |

11-1/2 |

11 |

|

1-29/32 |

1.900 |

1-1/2 |

11-1/2 |

11 |

|

2-3/8 |

2.375 |

2 |

8 |

11 |

|

2-7/8 |

2.875 |

2-1/2 |

8 |

11 |

|

3-1/2 |

3.5 |

3 |

8 |

11 |

|

4 |

4.0 |

3-1/2 |

8 |

11 |

|

4-1/2 |

4.5 |

4 |

8 |

11 |

|

5-5/8 |

5.563 |

5 |

8 |

11 |

|

6-5/8 |

6.625 |

6 |

8 |

11 |

Function

There are a vast number of types of fittings installed in hydraulic systems which perform different functions. The most common types are described in the table below:

|

Fittings which extend or terminate pipe lengths: |

||

|

Adapter |

Connects two dissimilar pipes to each other via solvent welding, soldering, or threading. |

Image Credit: Parker Hannifin |

|

Coupling |

Connects two similar pipes to each other via solvent welding, soldering, or threading. |

Image Credit: Stucchi Inc. |

|

Sleeve |

Connect two sections using mechanical fasteners (e.g. screws, anchors). Installation is typically quicker and simpler than a soldered or welded coupling connection. |

Image Credit: Tube-Mac Industries Ltd. |

|

Union |

Couplings which can be disconnected without cutting. Their connection (typically threading) allows for easy release. |

Image Credit: Grainger Industrial Supply |

|

Cap |

Covers the end of a section, attaching to a male connection via a weld, thread, solvent, or solder. |

Image Credit: Swagelok Company |

|

Plug |

Closes off the end of a system, attaching to a female connection via a weld, thread, solvent, or solder. |

Image Credit: Swagelok Company |

|

Fittings which add or change direction: |

||

|

Elbow |

Changes the direction flow to various angles. The most common angles are 90° and 45°, but 22.5° elbows are also made. |

Image Credit: Parker Hannifin |

|

Tee |

Connects three flow sections in a T-shaped intersection. This allows fluid flow to be combined or split apart. |

Image Credit: Parker Hannifin |

|

Cross |

4-way connections, providing one inlet and three outlets or vice versa. Crosses are less steady than tees, and can generate high stress on the vessel with temperature changes. |

Image Credit: Swagelok Company |

|

Fittings which connect pipes of smaller size: |

||

|

Reducer |

Includes all connections which connect between two or more vessels of different sizes. |

Image Credit: Tompkins Industries, Inc. |

|

Fittings which provide special connections or functions: |

||

|

Nipple |

Allows two separate fittings to be connected at each end. Standard nipples are straight with male threads on both ends. |

Image Credit: Parker Hannifin |

|

Valve |

Connects vessels together with the addition of a valve for the control of flow. For more information on types of valves, visit the Industrial Valves Selection Guide on GlobalSpec. |

Image Credit: Sinar Quality Internusa |

Specifications

Sizing

Once the type of fitting required has been determined, the most fundamental aspect of hydraulic fittings can be addressed: proper sizing. Proper sizing is essential to successful fitting selection, as oversized or undersized parts will either be completely incompatible or will seal or connect inadequately.

The two systems of measurement are Metric (mm) and English ("). The first step to proper sizing is selecting the appropriate measurement system for compatibility with the equipment or assemby being fitted.

The sizing of a hydraulic fitting is defined by the size of vessels it connects to. Tubes, hoses, and pipes are sized based on inside diameter (ID) and outside diameter (OD), measured in inches (in) or millimeters (mm). A fitting designed to connect to a tube with a 2" OD is rated as a 2" OD fitting. Inside diameter measures the diameter of the empty portion of the cylinder, while outside diameter includes the thickness of the tubing wall.

Operation

Hydraulic fittings are often specified to certain temperature and pressure ratings based on their design and construction.

- Operating pressure range is the working range of pressures or the pressure ratings at which the fitting was designed to operate, typically measured in pounds per square inch (psi). Operating above or below this rating could cause the fitting to fail (i.e. break, leak, lose its seal).

- Operating temperature range is the working range of temperatures or the temperature ratings at which the fitting was designed to operate, measured in degrees Fahrenheit (°F) or degrees Celsius (°C). Operating above or below this rating could cause the fitting to fail.

Standards

The dimensions and sizing of the most common hydraulic fittings follow standards set forth by SAE (Society of Automotive Engineers) International. These standards help to maintain size-consistency with old and new systems, making the replacement of fittings simpler and less costly. Standards also help clients procure fittings that work effectively within the range of pressures they are designed for. SAE standards for hydraulic fittings include:

SAE J514 - Hydraulic Tube Fittings

SAE J516 - Hydraulic Hose Fittings

Selection Tip: There are many factors that affect fitting performance at a given pressure. Therefore, pressure ratings for fittings listed in SAE standards should not be considered absolute. Testing should be conducted to ensure satisfactory and safe performance under the specific conditions of the client's application.

Materials

The essential material properties of hydraulic fittings are adequate strength and corrosion resistance. These are essential to safely handle high pressures characteristic of hydraulic systems, and to resist rust and corrosion from the hydraulic fluid inside the vessel. Other factors that play into material selection include cost and outside environmental conditions. Material choices include different types of plastic or metal.

Metals are used more commonly than plastics in most hydraulic systems because the high pressures necessitate higher strength materials.

- Aluminum - lightweight and corrosion resistant. By itself, aluminum has low tensile strength and is used for its corrosion resistance and low density in low pressure applications. It is alloyed with zinc, copper, silicon, manganese, and/or other metals to improve its strength and hardness.

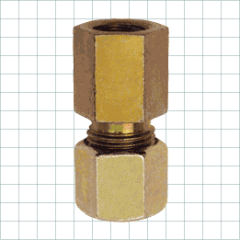

Brass - strong, durable, and corrosion resistant, with high temperature ductility and good conductivity. Brass is an alloy of copper and zinc, and is commonly used for smaller compression and threaded fittings because of its machinability and its excellent performance properties. Brass fittings can have various protective or decorative finishes which should match the finish of the piping. (Image Credit: Parker Hannifin)

Brass - strong, durable, and corrosion resistant, with high temperature ductility and good conductivity. Brass is an alloy of copper and zinc, and is commonly used for smaller compression and threaded fittings because of its machinability and its excellent performance properties. Brass fittings can have various protective or decorative finishes which should match the finish of the piping. (Image Credit: Parker Hannifin)

- Cast iron - strong and highly abrasion resistant. Iron fittings and systems are typically galvanized for increased corrosion resistance, but are still less common than standard steel in hydraulic systems.

Steel - durable and strong, with a high resistance to heat. Steel is an alloy of iron and carbon; it is typically alloyed with other metals to improve its corrosion resistance, which is essential in hydraulic applications where the fitting is in constant contact with fluids. Galvanized steel is coated with zinc for added rust protection and chemical corrosion resistance. (Image Credit: Parker Hannifin)

Steel - durable and strong, with a high resistance to heat. Steel is an alloy of iron and carbon; it is typically alloyed with other metals to improve its corrosion resistance, which is essential in hydraulic applications where the fitting is in constant contact with fluids. Galvanized steel is coated with zinc for added rust protection and chemical corrosion resistance. (Image Credit: Parker Hannifin)

Stainless steel - strong with excellent chemical and corrosion resistance. Stainless steel is an alloy of steel that contains over 10.5% chromium. It has the strength and durability of steel while also providing excellent corrosion resistance, making it the most suitable for hydraulic applications. Stainless steel is typically more expensive than fittings made from other materials. (Image Credit: Parker Hannifin)

Stainless steel - strong with excellent chemical and corrosion resistance. Stainless steel is an alloy of steel that contains over 10.5% chromium. It has the strength and durability of steel while also providing excellent corrosion resistance, making it the most suitable for hydraulic applications. Stainless steel is typically more expensive than fittings made from other materials. (Image Credit: Parker Hannifin)

Plastics have naturally higher resistance to corrosion than metals, but have lower strength and durability making them less suitable for high pressure hydraulic systems.

- Polypropylene (PP) - thermoplastic material that exhibits excellent cold flow, bi-axial strength, and yield elongation properties. It is the most common plastic used for hydraulic fittings because of its fair strength and durability, and its resistance to corrosion, UV, weathering, and ozone.

Polysulfone - thermoplastic material known for toughness and stability at high temperatures. It has rigidity and high strength through a temperature range of -100°C to 150°C. It is an expensive material used in specialty hydraulic applications. (Image Credit: Grainger Industrial Supply)

Polysulfone - thermoplastic material known for toughness and stability at high temperatures. It has rigidity and high strength through a temperature range of -100°C to 150°C. It is an expensive material used in specialty hydraulic applications. (Image Credit: Grainger Industrial Supply)

Features

Hydraulic fittings may incorporate a number of features that provide additional functions necessary for certain applications.

-

Connect-under-pressure fittings are design to allow installation or connection of the fitting while the system is under pressure.

-

Expansion joints and couplings connect sections of tube and provide allowance for movement due to service load, shock, or thermal cycles.

-

Flexible fittings have the ability to move without being damaged.

-

Lined fittings are manufactured with an integral lining. The linings are often made from engineered polymers for use with process materials or in applications such as food processing where media cleanliness is important.

-

Pre-insulated fittings consist of insulating materials or jacket constructions designed to insulate the vessel and media from outside temperatures.

-

Swivel feature allows one or more fitting ends to rotate or swivel.

References

HFI Fluid Power Products - Fitting Identification Guide

Hydraulic Fittings USA - Steel Hydraulic Fittings

- hydraulic decoking system

- SAE 6 hydraulic fittings

- bell reducer hydraulic fitting

- hose pusher hydraulic fitting

- pyrex pipe hydraulic fitting

- reusable hydraulic fittings

- SAE 8 hydraulic fittings

- socket weld hydraulic fittings

- 1/4 inch hydraulic fittings

- AutoCAD blocks pipe hydraulic fitting

- bump tube hydraulic fitting

- color coded hydraulic fittings

- equivalent length of straight pipe for various hydraulic fitting

- equivalent length pipe hydraulic fitting

- plumbers organizer hydraulic fitting

- SAE 4 hydraulic fittings

- steel hose hanger hydraulic fitting

- 1 4 hydraulic fittings

- 1/2 bsp hydraulic fittings

- 1/2 NPT hydraulic fittings

- 10000 PSI hydraulic fittings

- 12 mm hydraulic fittings

- 20000 PSI hydraulic fittings

- 3/4 bsp hydraulic fittings

- 3/8 hydraulic fittings

- 3/8 NPT hydraulic fittings

- 4000 PSI hydraulic fittings

- 5000 PSI hydraulic fittings

- AutoCAD drawings hydraulic fittings

- DIN 3865 hydraulic fittings