Products & Services

See also: Categories | Featured Products | Technical Articles | More Information-

Supplier: JC Cherry, Inc.

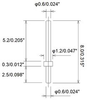

Description: Kovar Round Terminal Materials : Kovar Gold Flash over Ni plating

- Material: Other

-

Supplier: Leading Edge Metals & Alloys, Inc.

Description: Composed of iron, nickel and cobalt, Kovar®1 has thermal expansion characteristics similar to hard glass, making it an excellent choice for glass-to-metal hermetic seals. Kovar® is widely used in the electronics industry.

- Alloy: Yes

- Applications: Electronics / RF-Microwave

- Controlled / Low Expansion Alloy: Yes

- Metal / Alloy Types: Nickel / Nickel Alloy (UNS N), Refractory / Reactive (UNS R), Cobalt / Cobalt Alloy

-

Supplier: Houde Glass of NJ, Inc.

Description: 7052 Kovar Tubing (Alkali Barium Borosilicate)

- Coeff. of Thermal Expansion (CTE): 4.6 µm/m-C

- Glass Type: Borosilicate

- Shape / Form: Tube Stock

- Thickness / Wall Thickness: 0.0200 to 0.0350 inch

-

-

Supplier: Accuris

Description: WIRE,KOVAR,GOLD PLATED,ELECTRONIC

-

Description: Strip, Coil, Foil & Wire, ASTM F-15 APPLICATIONS Alloy 29-17 (Kovar®) has been used for making hermetic seals with the harder Pyrex glasses and ceramic materials. This alloy has found wide use in application where high reliability is a necessity. In power tubes

- Applications: Electrical / HV Parts, Electronics / RF-Microwave, Other

- Coil Stock: Yes

- Controlled / Low Expansion Alloy: Yes

- Elongation: 42 %

-

Supplier: RFMW

Description: WSMP Male PCB, Straight, SMT, J-Lead, FD, Hi Temp (Kovar/Glass)

-

Supplier: Atom Precision of America, Inc.

Description: Long tool life is achieved for mild steel materials hard-to-cut such as SU304, Kovar, Inconel etc. High stiffness tool design prevents the breakage in drilling hard-to-cut materials.

- Construction: Solid Construction

- Cutting Application: Steel, Stainless Steel

- Cutting Diameter: 0.1165 inch

- Drill Type: Microdrill

-

Supplier: Technic, Inc.

Description: Low pH gold strike with excellent adhesion on tin-nickel, stainless steel, Kovar, titanium, passive nickel and other difficult to plate base metals.

- Chemical / Process: Gold Plating

-

Supplier: Technic, Inc.

Description: Formulation used for improved adhesion over difficult to plate base materials such as Kovar, Alloy 52 and Stainless Steel prior to subsequent plating.

- Chemical / Process: Nickel Plating - Hard

-

Supplier: Materion Corporation

Description: the metalized windows to be sealed to a plated Kovar frame, with either a solder preform being tack welded to the Kovar frames or left bare for seam sealing. These assemblies hermetically seal various device packages.

- Antireflection Coating: Yes

- Materials: Germanium, Sapphire, UV Grade Fused Silica

-

Description: MIL-0-13830 optical windows from Qnnect, formerly Hermetic Solutions Group can be produced in almost any size or shape - round, square, or rectangular- to meet specific requirements. Glass material and shell material combinations include: borosilicate/Kovar F-15; soda lime/stainless steel

- Materials: Sapphire, Specialty / Other

- Window Shape: Circular

-

Supplier: Indium Corporation

Description: Indalloy Flux #4-OA is a clear liquid flux formulated for the purpose of soldering moderately easy to difficult metallizations such as nickel, oxidized copper, Kovar and brass. This flux contains organic salts in a water-free water-soluble solvent.

- Fluxes & Cleaners: Soldering Flux / Rosin

-

Supplier: Indium Corporation

Description: Indalloy Flux #5-OA is a clear liquid flux formulated for the purpose of soldering moderately easy to difficult metallizations such as nickel, oxidized copper, Kovar and brass. This flux contains organic salts in a water-free water-soluble solvent.

- Fluxes & Cleaners: Soldering Flux / Rosin

-

Supplier: Ed Fagan, Inc.

Description: ASTM F-15 Alloy, commonly known as Kovar, is a controlled expansion alloy consisting of 29% Nickel, 17% Cobalt, and balance Iron. Kovar is produced to ensure good properties for machining and deep drawing as well as porosity free product. Its expansion characteristics match both

- Applications: Electronics / RF-Microwave

- Controlled / Low Expansion Alloy: Yes

- Features: Cold Finished / Rolled / Drawn, Wrought

- Metal / Alloy Types: Other / Miscellaneous Ferrous Alloy (UNS K)

-

Supplier: Ed Fagan, Inc.

Description: ASTM F-15 Alloy, commonly known as Kovar, is a controlled expansion alloy consisting of 29% Nickel, 17% Cobalt, and balance Iron. Kovar is produced to ensure good properties for machining and deep drawing as well as porosity free product. Its expansion characteristics match both

- Applications: Electronics / RF-Microwave

- Controlled / Low Expansion Alloy: Yes

- Features: Cold Finished / Rolled / Drawn, Wrought

- Metal / Alloy Types: Other / Miscellaneous Ferrous Alloy (UNS K)

-

Supplier: Ed Fagan, Inc.

Description: ASTM F-15 Alloy, commonly known as Kovar, is a controlled expansion alloy consisting of 29% Nickel, 17% Cobalt, and balance Iron. Kovar is produced to ensure good properties for machining and deep drawing as well as porosity free product. Its expansion characteristics match both

- Applications: Electronics / RF-Microwave

- Coil Stock: Yes

- Controlled / Low Expansion Alloy: Yes

- Features: Cold Finished / Rolled / Drawn, Wrought

-

Supplier: Ed Fagan, Inc.

Description: ASTM F-15 Alloy, commonly known as Kovar, is a controlled expansion alloy consisting of 29% Nickel, 17% Cobalt, and balance Iron. Kovar is produced to ensure good properties for machining and deep drawing as well as porosity free product. Its expansion characteristics match both

- Applications: Electronics / RF-Microwave

- Controlled / Low Expansion Alloy: Yes

- Features: Cold Finished / Rolled / Drawn, Wrought

- Metal / Alloy Types: Other / Miscellaneous Ferrous Alloy (UNS K)

-

Supplier: Specialty Seal Group

Description: : Insulator-Glazed Ceramic 92-96% Al2O3 (white or pink) Feedthru Tube-Nickel, Kovar, Copper Weld Shealth/Flange-Nicke l, Kovar, 304 Stainless Steel Special Characteristics: High Abrasion Resistance High

- Feedthrough Type: Electrical

-

Supplier: Fairview Microwave Inc.

Description: frequency of 18 GHz. This Fairview Microwave SMP PCB connector has a kovar body with gold plating. Our SC5347 SMP connector uses kovar contact and a gold plating material. This SMP male PCB smooth bore RF connector is RoHS compliant, you can find this SMP male PCB smooth bore connector

- Connector Type: SMP

- Frequency Range: 18 GHz

- Geometry: Straight

-

Supplier: Specialty Seal Group

Description: strong. If a higher cycle range is needed, you should consider Kovar* Matched Seals. Specialty Seal Group uses a fundamental glass sealing process to manufacture glass seals in which the Kovar metal thermal expansion coefficient matches the glass thermal expansion coefficient. The

-

Supplier: Advanced Technology Group, Inc.

Description: inventory of raw material that can be quickly configured to your specific requirements. We invite you to explore our product offerings and contact us for any questions regarding your latest project. MATERIAL Center Conductor – Kovar, Gold plate min 50 micro inches thick over 50

- Materials: Other

-

Supplier: Advanced Technology Group, Inc.

Description: inventory of raw material that can be quickly configured to your specific requirements. We invite you to explore our product offerings and contact us for any questions regarding your latest project. MATERIAL Center Conductor – Kovar, Gold plate min 50 micro inches thick over 50

- Materials: Other

-

Supplier: Crane Aerospace & Electronics

Description: performance while still achieving the small size and low profile of surface mount devices. The Kovar input leads are designed to suit a variety of mounting situations simply by cutting them to the desired length.

- Average Power: 1 watts

- Coupler Type: Uni-Directional

- Coupling: 11 to 20 dB

- Directivity: 13 to 20 dB

-

Description: work to partner with you by building relationships based on trust and teamwork. Complex, multi-faceted parts. Prototype & product development. Medical, scientific, aerospace, laboratory, automotive. Titanium, 17-4 Stainless Steel, Kovar, Cobalt chromium, Copper, Ultem.

- Location: North America, United States Only, Northeast US Only

- Machining Capabilities: Drilling, Milling, Turning, Swiss Machining, Jig Boring, Broaching, Jig Grinding, Surface Grinding, Honing, Electrode EDM, Wire EDM, Other

- Materials: Composites, Copper, Hardened Metals, Plastics, Precious Metals, Rubber, Stainless Steel, Steel / Steel Alloys, Titanium, Other

- Secondary Operations: Anodizing, Black Oxide, Electroplating, Heat Treating / Stress Relieving, Lapping / Polishing, Welding

-

Supplier: OptiSpac, Inc.

Description: TOSA/ROSA package usually uses the Kovar metal ring frame gold tin brazing light window, high temperature brazing ceramic feed through component, metal heat dissipation bottom plate structure. This type of packaging package products have high integrated density, small volume and low cost, and

- Materials: Copper, Tungsten

-

Supplier: OptiSpac, Inc.

Description: The package is usually made of low-cost 10# steel material, and it can also be made of Kovar alloy materials under special requirements. This type of packaging package products use a stable and reliable pressure type glass melt sealing process. Supporting step etched cover plate meets the

- Materials: Steel, Other

-

Supplier: OptiSpac, Inc.

Description: The package adopts metal cavity brazing or melt seal feed through assembly, optical tube structure. WSS package cavity is usually large, generally using the Kovar alloy plate 6-side welding cavity structure (if the cavity is small, low cost aluminum alloy overall processing structure can be

- Materials: Aluminum, Copper, Tungsten

-

Supplier: Morgan Advanced Materials

Description: Hybralox™ pre-forms in a range of integrated circuit seal applications in both glass-to-metal and ceramic-to-metal varieties. The Hybralox™ 7000 Series is used to seal Kovar to Alumina bases and also in Kovar to Kovar sealing applications.

- Material Type: Alumina / Aluminum Oxide

-

Supplier: Advanced Technical Ceramics Company

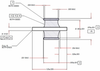

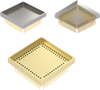

Description: Chemical Ceramic Milling AdTech manufactures high quality chemically milled products in Kovar, Alloy 42, Stainless and Spring Steel. Products include step lids, lead frames, seal rings as well as other custom product applications such as screens and micro channel plates. Products can be

- Location: North America, United States Only, Southern US Only

- Materials: Stainless Steel, Other

- Services: CAD / CAM Support, Design Assistance, Prototype Services, Low Volume Production, High Volume Production

-

Description: Vacuum Insulators (also known as vacuum breaks and isolators) are used to electrically isolate one component or system from another. Nor-Cal uses a ceramic insulator with 95% minimum aluminum oxide content, which is silver brazed to two Kovar sleeves, creating a UHV compatible insulator. The

- Configuration: All Ports Same Type

- Fitting Connection / Port Type(s): Flange

- Flange OD: 1.18 to 2.16 inch

- Flange and Fitting Seal / System: ISO-KF / ISO-QF (Small Clamped, <2")

-

Description: Vacuum Insulators (also known as vacuum breaks and isolators) are used to electrically isolate one component or system from another. Nor-Cal uses a ceramic insulator with 95% minimum aluminum oxide content, which is silver brazed to two Kovar sleeves, creating a UHV compatible insulator. The

- Configuration: All Ports Same Type

- Fitting Connection / Port Type(s): Flange

- Flange OD: 1.33 to 2.73 inch

- Flange and Fitting Seal / System: Conflat

-

Supplier: OptiSpac, Inc.

Description: The package design usually adopts ceramic ring frame high temperature brazing Kovar alloy metal sealing ring, metal heat dissipation bottom plate structure, shape structure, size and feed pipe foot number can be customized. This kind of packaging package product adopts a stable and reliable

- Materials: Other

-

Supplier: MacDermid Alpha Electronics Solutions

Description: , kovar, ceramics and high frequency fluoropolymers. The working life of STAYSTIK 8000 at 25°C is exceptional at 40 days based on DSC data. Features Meets MIL STD 883 requirements Extremely low outgassing Fast bonding to a variety of substrates

-

Supplier: Accu-Glass

Description: to metals that include Kovar, stainless steel, tungsten and titanium. The Accu-Glass precision glass forming processes provide the flexibility to produce low-volume prototypes or high-volume/low-cost production quantities.

- Applications: Electronics / RF-Microwave

- Shape / Form: Tube Stock

-

Vacuum Gauges and Instruments - Televac Glass Bayard-Alpert Hot Cathode Ionization Gauge -- ETI 8142Supplier: Fredericks Company - Televac

Description: Physical Data Tubulation: 3/4", 1" Pyrex® or Nonex® Glass or 3/4", 1" Kovar®, flanges are available Envelope: Nonex, platinum-coated interior Mounting Position: Vertical Collector: .005" Tungsten Filament: Thoria-coated Iridium or

- Media: Gas

-

Vacuum Gauges and Instruments - Televac Glass Bayard-Alpert Hot Cathode Ionization Gauge -- ETI 4336Supplier: Fredericks Company - Televac

Description: Physical Data Tubulation:3/4", 1" Pyrex® or Nonex® Glass or 3/4", 1" Kovar®, flanges are available Envelope: Nonex® 7720 Glass Mounting Position: Vertical Collector: .005" Tungsten Filament: Thoria-Coated Iridium or Tungsten

- Media: Gas

-

Supplier: Fairview Microwave Inc.

Description: frequency of DC and a maximum frequency of 8 GHz. SMP male hermetically sealed terminal limited detent RF connector has a glass dielectric type and a VSWR of 1.1:1. This Fairview Microwave SMP terminal connector has a kovar body with gold plating. Our SC5189 SMP connector uses kovar

- Connector Type: SMP

- Frequency Range: 8 GHz

- Geometry: Straight

-

Supplier: Fairview Microwave Inc.

Description: frequency of DC and a maximum frequency of 40 GHz. This Fairview Microwave SMP terminal connector has a kovar body with gold plating. Our SC5278 SMP connector uses kovar contact and a gold plating material. This SMP male hermetically sealed terminal full detent RF connector is RoHS

- Connector Type: RF and Microwave Connector

- Geometry: Straight

-

Supplier: Fairview Microwave Inc.

Description: frequency of DC and a maximum frequency of 40 GHz. This Fairview Microwave SMP terminal connector has a kovar body with gold plating. Our SC5280 SMP connector uses kovar contact and a gold plating material. This SMP male hermetically sealed terminal full detent RF connector is RoHS

- Connector Type: RF and Microwave Connector

- Geometry: Straight

-

Supplier: Fredericks Company - Televac

Description: of glass-to-glass and glass-to-element sealing. Specialized techniques have been developed for sealing many uncommon materials, including Kovar, sapphire, germanium, and platinum. Precision grinding, polishing, and sealing equipment have allowed Fredericks to achieve tolerances to less than

-

Supplier: Morgan Advanced Materials

Description: Hybralox™ pre-forms in a range of integrated circuit seal applications in both glass-to-metal and ceramic-to-metal varieties. The Hybralox™ 6000 Series can be used to seal Kovar to Alumina bases.

- Material Type: Alumina / Aluminum Oxide

-

Supplier: Morgan Advanced Materials

Description: Hybralox™ pre-forms in a range of integrated circuit seal applications in both glass-to-metal and ceramic-to-metal varieties. The Hybralox™ 5000 Series can seal to itself or to Kovar directly without metallisation.

- Material Type: Alumina / Aluminum Oxide

-

Supplier: Materion Corporation

Description: stamped from base materials of Kovar, A42, Copper or Nickel that are then plated with Ni and/or Ni and Au. This type of preform is an excellent "heat spreader" within an electronic package. It’s available in size from 0.005” thick to 0.015” in length and width. Shapes include squares,

- Applications: Electronics / RF-Microwave

- Clad / Bimetal: Yes

- Metal / Alloy Types: Other / Miscellaneous Nonferrous (UNS M)

- Shape / Form: Semi-finished Shape / Mill Stock, Bar Stock, Squares / Square Bar

-

Supplier: Crane Aerospace & Electronics

Description: performance. The Kovar leads are supplied untrimmed (unless otherwise specified) to allow mounting the package in a variety of configurations. 3. Merrimac offers a broad selection of Double Balanced Mixers ideal for a variety of signal processing functions from 20 kHz to 20 GHz. 4. Merrimac

- Conversion Loss: 7 to 10 dB

- IF Frequency Range: 0.0 to 1000 MHz

- LO - IF Isolation: 20 dB

- LO - RF Isolation: 35 dB

-

Supplier: Crane Aerospace & Electronics

Description: profile required of surface mount devices. The Kovar input leads extend beyond the package wall to facilitate inspection. In all units except the DMG-4B-1700, the internal components and connections are compatible with IR and vapor phase mounting of the device on a PCB. Hand soldering is

- Conversion Loss: 6 to 10 dB

- IF Frequency Range: 0.0 to 1000 MHz

- LO - IF Isolation: 20 to 25 dB

- LO - RF Isolation: 25 to 35 dB

-

Supplier: Morgan Advanced Materials

Description: and heavy industry equipment. Foil, wire and powder alloys are available in the following: * Cu and Cu alloys (CuNi) * Ni and Ni Alloys (Monel, Alumel) * NiFe and NiFeCo alloys (Kovar) * Mo, Ni, W, Ta, Pt, Ti * 400 Series SST (410, 430) * 300 Series SST (304, 316, 321) * Inconels

- Form / Shape: Powder, Solid Wire, Strip / Sheet / Foil

- Melting Range: 1776 to 1875 F

-

Supplier: SPIE - Education

Description: dissipation, thermal stresses, warpage, alignment, weight, size, cost, and manufacturing yield. Decades-old traditional low-coefficient-of-t hermal-expansion (CTE) materials like tungsten/copper, molybdenum/copper, copper-Invar-copper, "Kovar", etc., have thermal conductivities that are no

- Industry: Electronics

- Modality: On-site / In Plant

- Technology / Subject: Electronics, Photonics / Optics

- Type: Course

-

Supplier: Advanced Technical Ceramics Company

Description: AdTech Ceramics is the US leader in manufacturing ceramic feedthroughs for use in military, aerospace, medical, and high reliability industrial applications. Ceramics are extremely reliable in high vacuum applications and compatible with metals such as Titanium, AlSi, Kovar, Alloy 42, CuMo

-

Supplier: First Sensor AG

Description: First sensors piezo resistive pressure sensors of the K-series STARe A/G are based on the High Stability Line STARe. The sensor elements are mounted on a Kovar TO-8 header. The header is additionally equipped with a high accuracy PTC temperature sensor. The K-Series STARe is supplied with a

- Device Category: Sensor

- Operating Temperature: -40 to 257 F

- Pressure Reading: Absolute, Gauge

- Working Pressure Range: 0.8702 to 5801 psi

-

Supplier: First Sensor AG

Description: First sensors piezo resistive pressure sensors of the K-series STARe D are based on the High Stability Line STARe. The sensor elements are mounted on a Kovar TO-8 header. The header is additionally equipped with a high accuracy PTC temperature sensor. The K-Series STARe is supplied with a

- Device Category: Sensor

- Operating Temperature: -40 to 257 F

- Pressure Reading: Differential

- Working Pressure Range: 0.4351 to 145 psi

-

Supplier: Summit Corporation of America

Description: plated overall Individual Parts and Components - overall/selective and vibratory plating Plating and Selective plating of chemically etched materials - Copper, brass alloys, Kovar, alloy 42

- Additional Services: Electropolishing, Pickling / Chemical Deburring

- Electroless: Yes

- Industry: Aerospace, Automotive, Castings / Cast Metal, Chemical / Material Processing, Electronics, Marine, Medical / Healthcare, Military Specification, OEM / Industrial, Process Equipment, Steel / Metal Mills

- Location: North America, United States Only, Northeast US Only

-

Supplier: TE Connectivity

Description: Body Features Body Material : Kovar Alloy Body Material Finish : Plated Body Plating Material : Gold Body Underplating Material : Nickel Configuration Features

- Gender: Male / Plug

- Number of Contacts: 1 #

-

Supplier: Micro Sensor Co., Ltd.

Description: is widely used for measuring pressure which is compatible with stainless steel and FKM. Electrical Performance • Power supply: =2.0mA DC • Electrical connection: f0.5mm Kovar pin or 100mm silicon rubber flexible wires • Common mode voltage

- Device Category: Sensor

- Pressure Reading: Absolute, Gauge

- Sensor Technology: Piezoelectric

Find Suppliers by Category Top

Featured Products Top

-

Fe Alloys & NiFeCO (Kovar) 94%-99% Al2O3 Kovar ; Copper Cored Kovar 300 & 400 Series SST Al (read more)

Fe Alloys & NiFeCO (Kovar) 94%-99% Al2O3 Kovar ; Copper Cored Kovar 300 & 400 Series SST Al (read more)

Browse Industrial Ceramic Materials Datasheets for Xiamen Innovacera Advanced Materials Co., Ltd.

Conduct Research Top

-

Heating a Kovar tube for a glass sealing application [PFS]

The client was using a torch, and operator error was slowing the heating. The repeatability of induction enables improved throughput while in this process it is a more efficient heating method than torch heating, also reducing scrap...

-

Heating a Kovar tube for a glass sealing application [IH]

The client was using a torch, and operator error was slowing the heating. The repeatability of induction enables improved throughput while in this process it is a more efficient heating method than torch heating, also reducing scrap...

-

Hermetically Sealing a Fiber Optic Cable in a Kovar Ferrule (.pdf)

The coil heats quickly so that the heat does not travel to heat sensitive components in the case...

-

Alloy

Alloy 42 is a family of nickel iron alloys, suitable for joining to ceramic chips in electronic circuits, as well as glass-to-metal joining applications such as leaded windows and cathode tubes. It is a relatively inexpensive alternative to other electronic alloys such as Kovar. The medical

More Information Top

-

An experimental/analytical comparison of strains in encapsulated assemblies

setup, designed to measure in situ strains, consisted of thin. closed-end, Kovar * tubes that were instrumented …

-

Actin-based Motility

David R. Kovar , Andrew J. Bestul, Yujie Li, and Bonnie J. Scott .

-

http://dspace.mit.edu/bitstream/handle/1721.1/89307/48815447-MIT.pdf?sequence=2

Kovar Tube Finning Model .

-

Effects of package geometry, materials, and die design on energy dependence of pMOS dosimeters

… insulator parts were in ceramic packages whereas the other type was in both ceramic and kovar cans.

-

ZCP2008IHC718

D LOSS AS A FUNCTION OF TEMPERATURE IN ERD2 FILMS ON KOVAR WITH AND WITHOUT AN INTERMEDIATE …

-

http://dspace.mit.edu/bitstream/handle/1721.1/9248/45536381-MIT.pdf?sequence=2

14 Figure 1-5: Relative thermal expansion of Kovar , Steel, and Silicon .............................

-

Novel hermetic packaging methods for MOEMS

Key words: MOEMS packaging, glass-to-metal seal, kovar , hermetic, diffusion bonding, window, lid .

-

New Silver Paste for Die-Attaching Ceramic Light-Emitting Diode Packages

… materials, the thermal expansion of the Ag sintered layer was reduced by the addition of Kovar particles.

Indicates content that may require registration and/or purchase.

Indicates content that may require registration and/or purchase.