Design for Manufacturability Handbook, Second Edition

There are a variety of machining processes by which holes are produced. This chapter deals with the conventional, traditional methods drilling, reaming, boring, etc. and the design of workpieces to facilitate such operations.

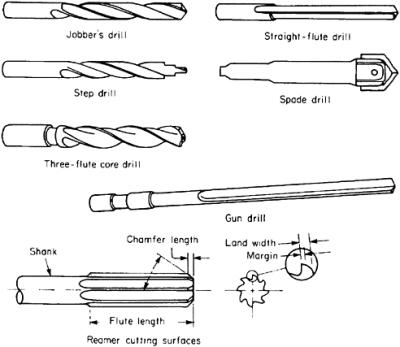

Drilling is a machining process in which a round hole is produced or enlarged by means of an end-cutting rotating too, a drill. Reaming is a related process in which an existing round hole is enlarged to accurate size (diameter and straightness) and smooth finish by means of an end-cutting rotating tool, a reamer. Figure 4.5.1 illustrates some typical drills and a typical reamer.

With drills, the width of the cut from each flute usually is the full radius of the tool; in reaming, only 0.13 to 0.38 mm (0.005 to 0.015 in) is removed from each side of the hole. Reamers are run at about two-thirds the rotary speed of drills of the same diameter but are fed about 50 percent more per revolution.

Drill fixtures or jigs are employed in production drilling to locate the hole accurately in the work. A bushing serves to guide the drill. Reamers may be fed through a fixed bushing to ensure the most accurate hole location, but in many cases they are simply allowed to float and follow the location and direction of the drilled hole.

Boring is a machining operation that enlarges an existing hole by removing metal with a rigidly mounted single-point cutting tool. Either...