Working Guide to Process Equipment, Third Edition

Air coolers are twice as expensive to purchase and install as water coolers. The great advantage of an air cooler is that it does not need cooling water. The difficult aspect of air cooling arises from the flow of air across the tubes.

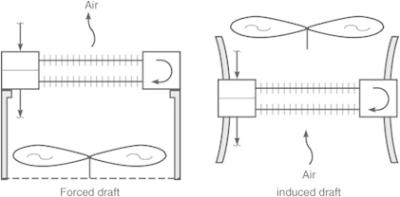

Most air coolers are either induced-draft or forced-draft, as shown in Fig. 17.1, the more common arrangement being forced draft. The air is moved by rather large fans. The tubes are surrounded with foil-type fins, typically 1 in high. The surface area of the fins as compared to the surface area of the tubes is typically 12 to 1. That is why we call an air cooler an extended-surface heat exchanger.

The heat-transfer coefficient of an air cooler (Btu, per hour, per square foot of finned area, per degree Fahrenheit) is not particularly good. It might be 3 to 4 for cooling a viscous liquid, or 10 to 12 for condensing a clean vapor. The low heat-transfer coefficients are offset by the large extended surface area.

In a forced-draft air cooler, cool air is blown through the underside of the fin tube bundle. In an induced-draft air cooler, cool air is drawn through the underside of the fin tubes. Either way, road dust, dead moths, catalyst fines, and greasy dirt accumulate along the lower row of tubes. As the tubes foul, they offer more resistance to the airflow. However, note that

The total airflow discharged...