Chemical Engineering License Review, Second Edition

A control valve is a variable opening used to regulate the flow of a process fluid as required by the process. The three important aspects of a control valve are capacity, characteristics, and rangeability.

Capacity This is expressed in terms of C v, the flow coefficient, which is the flow of water at 60 F in gallons per minute at a pressure drop of 1 psi across the valve when it is completely open.

Characteristics This is the relationship between the change in the valve opening and the change in the flow through the valve, viz., equal percentage, linear and nonlinear.

Rangeability This is the ratio of the maximum controllable flow to the minimum controllable flow. In terms of C v, the rangeability R is given by

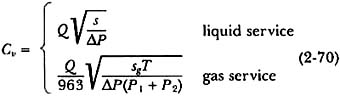

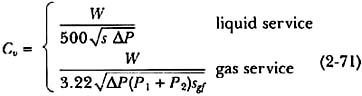

The formulas used for control valve sizing are as follows:

Volumetric flow:

Mass flow:

| where C v | = valve coefficient |

| Q | = flow rate, gpm for liquid, ft 3/min for gases and vapors |

| s | = specific gravity at flowing temperature (water s at 60 F = 1) |

| ? P | = pressure drop across valve, psi |

| W | = flow rate, lb/h |

| s g | = specific gravity of gas relative to air |

| = | |

| s gf | = s g (520/T) |

| T | = flow temperature, R |

| P 1 | = upstream pressure, psia |

| P 2 | = downstream pressure, psia |

In terms of ? P and Q (gpm) the rangeability...