Products & Services

See also: Categories | Featured Products | Technical Articles | More Information-

Description: High quality and long life quality assurance, Suntech provide standard and custom parts for internationally renowned companies ASM, Hesse, Cho-Onpa, F&K Delvotec Bondtechnik, Palomar Technologies, DIAS Automation, West-Bond, Hybond, TPT, etc.Take modified nano-alumina powder, advanced forming

- Type: Wedge Bonder

-

Supplier: Palomar Technologies, Inc

Description: The newest Palomar fully automated, thermosonic high-speed, ball-and-stitch fine wire bonder capable of ball bumping and customized looping profiles. Based on Palomar’s proven wire bonder design and incorporating the latest productivity technology and operator ergonomics,

- Automation: Automatic

- Type: Thermosonic Ball Bonder

-

Supplier: Palomar Technologies, Inc

Description: Overview The Palomar 9000 Wedge Bonder is a high-speed fine wire wedge and ribbon bonder with optional interchangeable clamps for 45-60° and 90° deep access bonding on a single machine. The large 304 x 152mm work area provides users flexibility to work with many different

- Automation: Automatic

- Type: Wedge Bonder

-

-

Supplier: Palomar Technologies, Inc

Description: Overview The Palomar 8000i Wire Bonder is a fully automated thermosonic high-speed, ball-and-stitch wire bonder capable of ball bumping, stud bumping, wafer bumping, chip bumping, and customized looping profiles. Its patented Dual Z-Axis bond head enables very

-

Description: High quality and long life quality assurance, Suntech provide standard and custom parts for internationally renowned companies ASM, Hesse, Cho-Onpa, F&K Delvotec Bondtechnik, Palomar Technologies, DIAS Automation, West-Bond, Hybond, TPT, etc. Take modified nano-alumina powder, advanced

-

Description: Used as interconnect pads or bonding islands for gold and aluminum wire bond applications, wire bond tabs are a cost-effective and flexible technology used throughout the microelectronics industry.

-

Supplier: Linde Advanced Material Technologies

Description: Without the right coating material, even the highest-quality spray equipment can deliver low-quality coatings. That's why we engineer and manufacture a wide variety of TAFA® wires-from traditional metal and metal alloy to complex cored wire compositions-for all of your arc spray

- Shape / Form: Wire / Shaped Wire

-

Supplier: Materion Corporation

Description: Materion Microelectronics & Services bonding wire and ribbon is manufactured using a proprietary hydrostatic extrusion process, providing a cleaner and more uniform wire. The extrusion process eliminates imperfections due the extreme pressure that envelops the metal as it passes

- Applications: Electronics / RF-Microwave

- Metal / Alloy Types: Other / Miscellaneous Nonferrous (UNS M)

- Shape / Form: Semi-finished Shape / Mill Stock, Bar Stock, Rod / Round Bar Stock

-

Supplier: Total Plastics, Inc.

Description: White Polyurethane Foam Bonding Tape for Interior Use. Retail Packaging Circuit Board Mounts Signs Security Pads Component Mounts Wire/Cable Mounts Appliance Emblems Mirror Mounting Wall Displays Interior Trim and Ornamentation Tiles and Panels Kick Panels Panel Stiffner Attachment

- Adhesive: Acrylic

- Carrier / Backing Material: Foam

-

Supplier: Accuris

Description: BOND WIRE MODELING STANDARD

-

Supplier: Accuris

Description: BONDING WIRE SOCKET

-

Supplier: Accuris

Description: THERMOCOMPRESSION WIRE BONDING

-

Supplier: SAE International

Description: Technical Standard

-

Supplier: Richardson RFPD

Description: The 91 Series of chip capacitors features silicon nitride/silicon dioxide dielectric layers for high reliability and stable capacitance over time. These metal-insulator-semi conductor (MIS) capacitors have high insulation resistance and low dissipation factor for excellent high frequency performance

- Capacitance Range: 2.30E-5 microF

- DC Rated Voltage Range (WVDC): 100 volts

-

Supplier: Richardson RFPD

Description: The 90 Series of chip capacitors features silicon nitride/silicon dioxide dielectric layers for high reliability and stable capacitance over time. These metal-insulator-semi conductor (MIS) capacitors have high insulation resistance and low dissipation factor for excellent high frequency performance

- Capacitance Range: 4.70E-5 microF

- DC Rated Voltage Range (WVDC): 50 volts

-

Supplier: Richardson RFPD

Description: Richardson RFPD, an Arrow Company, is a specialized electronic component distributor providing design engineers with deep technical expertise and localized global design support for the latest new products from the world's leading suppliers of RF, Wireless, Energy and Power Technologies.

-

Supplier: Richardson RFPD

Description: MIS Chip Capacitors

- Capacitance Range: 4.70E-5 microF

-

Supplier: Producto Electric Corp.

Description: ZINC PLATED STEEL MATERIAL THREADED INSTALLATION 1.14 INCH DIAMETER 0.2 INCH THICKNESS 100 STANDARD PACKAGE 1/2 INCH TRADE SIZE APPLICABLE STANDARD NEMA FB-1 GL MODEL

- Material: Other

- Terminal Type: Other

-

Supplier: Producto Electric Corp.

Description: ZINC PLATED STEEL MATERIAL THREADED INSTALLATION 1.75 INCH DIAMETER 0.2 INCH THICKNESS 100 STANDARD PACKAGE 1 INCH TRADE SIZE APPLICABLE STANDARD NEMA FB-1 GL MODEL

- Material: Other

- Terminal Type: Other

-

Supplier: Producto Electric Corp.

Description: ZINC PLATED STEEL MATERIAL THREADED INSTALLATION 4.17 INCH DIAMETER 0.25 INCH THICKNESS 50 STANDARD PACKAGE 3 INCH TRADE SIZE APPLICABLE STANDARD NEMA FB-1 GL MODEL

- Material: Other

- Terminal Type: Other

-

Supplier: Producto Electric Corp.

Description: ZINC PLATED STEEL MATERIAL THREADED INSTALLATION 6.43 INCH DIAMETER 0.47 INCH THICKNESS 5 STANDARD PACKAGE 5 INCH TRADE SIZE APPLICABLE STANDARD NEMA FB-1 GL MODEL

- Material: Other

- Terminal Type: Other

-

Description: Standardizes the first order modeling of bond wires and the way bond wires are modeled in three dimensional electromagnetic field solvers. Describes the modeling of a bond wire from an integrated circuit die to a package lead in a ball or wedge type

-

Supplier: Linde Advanced Material Technologies

Description: Without the right coating material, even the highest-quality spray equipment can deliver low-quality coatings. That's why we engineer and manufacture a wide variety of TAFA® wires-from traditional metal and metal alloy to complex cored wire compositions-for all of your arc spray

- Thermal Spray Technology: Arc Spray (Electric Wire Arc)

-

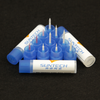

Description: Superior electrode material assures the lifespan of EFO wand and consistent shape and size of free air ball. The tip of EFO wands are made of by Iridium, platinum & Iridium alloy or platinum, it can keep the consistent shape and size duringthe 1063°C flame process. Quality Control Ageing processMost

- Automation: Automatic

- Type: Wedge Bonder

-

Supplier: Samsung Electro-Mechanics

Description: This is a semiconductor chip the size of which is more than 80% of that of the finished part. It is called WBCSP (Wire Bonding CSP) as a gold wire bonding method is applied to connect the semiconductor chip and the PCB. As a separate bonding facility is used, the

- Mounting: SMT

-

Supplier: Accuris

Description: TORQUE REQUIREMENTS FOR BOND WIRE PENETRATION OF BONDING SET SCREW

-

Supplier: SAE International

Description: No scope available.

-

Supplier: Hernon Manufacturing, Inc.

Description: 117 develops handling strength within seconds and full functional strength in a few hours. Instantbond® 117 can bond a wide variety of surfaces including metals, thermoplastics, elastomers, ceramics, leather, cork, and paper, but is particularly suited for wire tacking applications.

-

Supplier: Hernon Manufacturing, Inc.

Description: Ultrabond® 55711 is a single component anaerobic and UV curable, paste-like sealing compound formulated to provide instant sealing and bonding of electrical connectors. Upon exposure to UV energy an outer cured skin will be formed to prevent migration of the sealant out of the connector

-

Supplier: TEGAM, Inc.

Description: Widest 4-Wire Probes Selection. Uncomplicated, Back-lit Display 3-Year Warranty Made in the USA 17025 Calibration Option TEGAM Bond Meters for Your Industry Perform on-site calibration and

- Display Digits: 4 Digits

- Display Type: Digital

- Features: Battery Powered

- Form Factor: Handheld

-

Description: thermal transfer, at low cost are important. This sensor is typically used in energy management and thermal compensation for consumer, industrial and medical devices. It features a very small size of 0.75mm x 0.75mm with very low drift and can be packaged and integrated with semiconductor devices,

- Length: 0.0295 inch

- Nominal Resistance: 1000 R0 @ 0° C

- Operating Temperature: -58 to 302 F

- Sensor Technology: Wire Wound

-

Supplier: Techsil Limited

Description: , high strength and good adhesion. Recommended for general bonding, adhesion of yokes and magnets, sealing electric components, fixing of connection wires, filing and adhesion of laminar gaps and encapsulation of relays. Off white in colour, cures to a 86 Shore D material. Product

- Cure Type / Technology: Thermosetting / Crosslinking

-

Supplier: Utmel Electronic Limited

Description: 15 male D-Sub Wire bonding 2 3A - D-Sub/DVI/HDMI Connectors ROHS

-

Description: Describes three test methods to determine the bond strength of impregnating agents such as solvent-based varnishes and solventless resins. The three test methods most commonly used are: Twisted coil test, Helical coil test, Wire bundle test.

-

Supplier: Transcat, Inc.

Description: of Wenner or Schlumberger test method 2- and 4-Wire DC resistance measurement (Bond testing) with automatic polarity reversal Ground Resistance with 2 clamps (no auxiliary rods) Ground Resistance of Pylons with the GroundFlex® Adapter Model 6474 and GroundFlex®

-

Supplier: Saint-Gobain Tape Solutions

Description: Norbond V9000 series natural color polyurethane foam bonding tapes are ideal for a variety of electronic and general bonding applications. Norbond V9000 is UL listed as an electrical component (UL746C). Applications: Appliance emblems Signs Kick panels Circuit board mounts Electrical

- Adhesive: Acrylic

- Temperature Resistance: -34 C

- Thickness: 0.0150 to 0.1260 inches

- Type: Single-Sided Adhesive

-

Description: New England Wire Technologies is well known as a manufacturer of high-quality braided wire products. We product braids for diverse applications such as ground strap, motor brush leads, circuit breaker shunts as well as for mechanical and electrical protection of single and

- Cable Conductor: Copper and Copper Alloys

- North American (AWG): 2 to 22 AWG

-

Supplier: Saint-Gobain Tape Solutions

Description: Norbond V1300 series bonding tapes combine a white polyurethane foam substrate with a durable, pressure-sensitive acrylic adhesive on both sides. The foam properties dissipate vibrations and distribute stress forces, while the adhesive maintains a long-term bond. Applications

- Adhesive: Acrylic

- Temperature Resistance: -34 C

- Thickness: 0.0315 to 0.1260 inches

- Type: Double-Sided

-

Supplier: Utmel Electronic Limited

Description: 9 Female D-Sub Wire bonding 2 260?@ 3A -25?~+105? Plugin D-Sub/DVI/HDMI Connectors ROHS

- Gender: Male / Plug

-

Supplier: Utmel Electronic Limited

Description: 26 male D-Sub Wire bonding 3 260?@ 5A -25?~+85? Plugin D-Sub/DVI/HDMI Connectors ROHS

- Gender: Male / Plug

-

Supplier: Utmel Electronic Limited

Description: 15 male D-Sub Wire bonding 3 260?@ 5A -25?~+85? Plugin D-Sub/DVI/HDMI Connectors ROHS

- Gender: Male / Plug

-

Supplier: Saint-Gobain Tape Solutions

Description: Norbond® polyurethane tapes combine a high-density polyurethane foam substrate with high-performance acrylic adhesive on both sides. The foam substrate absorbs stress and distributes stress forces over the entire bond line. Available in black, gray, white and off-white colors

- Foam Type: Flexible

- Material / Composition: Plastic / Polymer

-

Supplier: Saint-Gobain Tape Solutions

Description: Norbond® polyurethane tapes combine a high-density polyurethane foam substrate with high-performance acrylic adhesive on both sides. The foam substrate absorbs stress and distributes stress forces over the entire bond line. Available in black, gray, white and off-white colors

- Foam Type: Flexible

- Material / Composition: Plastic / Polymer

Find Suppliers by Category Top

Featured Products Top

-

Abstract This application note describes the LED/IC wire bonder ecosystem (market drivers, architectures, timings…) and focus specifically on the main technical challenges for the motion control part. The selection of the control architecture and its position encoders (read more)

Abstract This application note describes the LED/IC wire bonder ecosystem (market drivers, architectures, timings…) and focus specifically on the main technical challenges for the motion control part. The selection of the control architecture and its position encoders (read more)

Browse Motion Controllers Datasheets for ETEL S.A. -

Wedge capillary is an important tool for wire bonding. It can be made of tungsten carbide (hard alloy), titanium carbide and ceramic. The head of the wedge capillary is wedge. There is a through-hole on the back of wedge capillary for passing the bonding wire, and the hole diameter (read more)

Wedge capillary is an important tool for wire bonding. It can be made of tungsten carbide (hard alloy), titanium carbide and ceramic. The head of the wedge capillary is wedge. There is a through-hole on the back of wedge capillary for passing the bonding wire, and the hole diameter (read more)

Browse Semiconductor Wire and Wedge Bonders Datasheets for Suntech Applied Materials (Hefei) Co.,Ltd -

In order to achieve more efficient and reliable bonding with silver alloy wire, the specially treated texture of Suntech ceramic capillary is recommended, which has been proven to enhance the coupling interface between the capillary tip surface and the silver alloy wire, providing more efficient ultrasonic energy transfer.

(read more)

Browse Semiconductor Wire and Wedge Bonders Datasheets for Suntech Applied Materials (Hefei) Co.,Ltd -

The Kyocera AVX WBR Series of top contact, wire (read more)

The Kyocera AVX WBR Series of top contact, wire (read more)

Browse Chip Resistors Datasheets for Richardson RFPD -

In the dynamic landscape of semiconductor devices, cost-effectiveness is the key to staying competitive. Embracing this ethos, the utilization of copper wire as a bonding material has surged due to its affordability and excellent mechanical and electrical conductivity. The copper wire (read more)

In the dynamic landscape of semiconductor devices, cost-effectiveness is the key to staying competitive. Embracing this ethos, the utilization of copper wire as a bonding material has surged due to its affordability and excellent mechanical and electrical conductivity. The copper wire (read more)

Browse Semiconductor Wire and Wedge Bonders Datasheets for Suntech Applied Materials (Hefei) Co.,Ltd -

Wedge-shaped capillaries serve a pivotal role in microelectronics bonding processes, notably in ultrasonic wire bonding. Designed for precise pressure application, they facilitate efficient soldering, ensuring optimal joint morphology and quality. These capillaries find extensive application in (read more)

Wedge-shaped capillaries serve a pivotal role in microelectronics bonding processes, notably in ultrasonic wire bonding. Designed for precise pressure application, they facilitate efficient soldering, ensuring optimal joint morphology and quality. These capillaries find extensive application in (read more)

Browse Semiconductor Wire and Wedge Bonders Datasheets for Suntech Applied Materials (Hefei) Co.,Ltd -

materials that meet the needs of the specific applications. We routinely supply Litz wire constructions using magnet wires with standard NEMA and IEC enamels. We have also designed and manufactured Litz wire, both rounded and shaped, using bondable, fluoropolymer coated, ceramic or glass fiber (read more)

materials that meet the needs of the specific applications. We routinely supply Litz wire constructions using magnet wires with standard NEMA and IEC enamels. We have also designed and manufactured Litz wire, both rounded and shaped, using bondable, fluoropolymer coated, ceramic or glass fiber (read more)

Browse Litz Wire Datasheets for New England Wire Technologies Corporation -

Conax Technologies’ PL Insulated Lead Wire Feedthrough Conax Technologies’ Model PL (Power Lead (read more)

Conax Technologies’ PL Insulated Lead Wire Feedthrough Conax Technologies’ Model PL (Power Lead (read more)

Browse Electrical Feedthroughs Datasheets for Conax Technologies -

Capillary aging poses a significant challenge in wire bonding processes, impacting solder joint quality and overall reliability. As capillaries undergo multiple bonding cycles, they accumulate wear and contaminants, leading to degraded performance. This phenomenon manifests through deteriorating (read more)

Capillary aging poses a significant challenge in wire bonding processes, impacting solder joint quality and overall reliability. As capillaries undergo multiple bonding cycles, they accumulate wear and contaminants, leading to degraded performance. This phenomenon manifests through deteriorating (read more)

Browse Semiconductor Wire and Wedge Bonders Datasheets for Suntech Applied Materials (Hefei) Co.,Ltd -

Ceramic capillaries are the primary tools used for wire bonding. Under the influence of pressure, heat, and ultrasonic vibration, these capillaries are used to bond wires with diameters ranging from 0.025mm to 0.050mm onto solder pads or pins. (read more)

Browse Semiconductor Wire and Wedge Bonders Datasheets for Suntech Applied Materials (Hefei) Co.,Ltd

Conduct Research Top

-

Introduction of Wedge Capillary for Wire Bonding

Wire bonding is currently the mainstream connection method for semiconductors packaging. Commonly used wire bonding welding methods include thermocompression welding, ultrasonic welding and ultrasonic thermocompression welding. Wire bonding can be categorised as ball bonding and wedge bonding

-

Advanced Motion Control for Wire Bonding

This application note describes the LED/IC wire bonder ecosystem (market drivers, architectures, timings...) and focus specifically on the main technical challenges for the motion control part. The selection of the control architecture and its position encoders have a significant contribution

-

Ceramics Capillary for Copper Wire Bonding

Wire bonding is to weld the two ends of the lead to the chip pad and the lead frame respectively in a certain environment by means of thermal ultrasonic pressure, so as to realize the connection between the internal circuit and the external circuit of the chip. Up to now, the lead metal materials

-

Ceramics Capillary for Improving Wire Bonding Efficiency

Wire bonding technology in semiconductors packaging, developed in the 1950's is one of the oldest and lowest cost interconnection solutions. It uses wire to bond by machines made from ASM Pacific, K&S, etc. similar to high-tech sewing machines; thin threads sew one chip onto another chip

-

Justifying the Purchase of Die or Wire Bonder Equipment

performing significantly better than the old equipment. To get the final approval, those engineers need to convert their technical ideas into a monetary calculator and provide proof that the company's investment in new die bonding or wire bonding equipment is essentially worth its weight in gold.

-

Reliable Wire Bonding Through Quality Data Collection for Industry 4.0

Wire bonding and sintering are critical processes involved in the manufacture of a majority of electronic devices. These processes are used to connect silicon chips, integrated circuits (ICs), and electrical components to their housings and boards. Wire bonding has become one of the most widespread

-

Improve Wire Bond Capability and Reliability through Use of Auxiliary Wires

Palomar Technologies offers a variety of Auxiliary wire options for our Wire/Ball bonder. Auxiliary wires are commonly defined as an additional wire outside of a normal ball-to-stitch wire bond. Whether it be a pre-wire, generally referred to as stand-off stitch, or a post-wire, also known

-

Brief Introduction for Gold Wire Bonding and Laser Welding of Pressure Sensors

It is necessary to introduce in advance that all operations performed by the Micro Sensor must be completed in a clean and dust-free environment in the purification workshop, and have very high requirements for the level of technology. First of all, let's introduce gold wire bonding, also known

More Information Top

-

Force Sensors for Microelectronic Packaging Applications

5.1 Wire Bonder Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

Advanced Wirebond Interconnection Technology

2.3.5: 2.3.6: 2.3.7: Hydrostatic Extrusion Annealing Winding and Spooling 2.3.7.1: Spooling for Manual Bonders Application 2.3.8: Spooling for High Speed Automated Wire Bonders 2.3.8.1: Types of Spools 2 …

-

http://calhoun.nps.edu/public/bitstream/handle/10945/27897/12Dec_Roth_John.pdf?sequence=1

Wire Bonder Setup and Use.............................................................

-

Vibration, Structural Engineering and Measurement I

The Spectral Analysis of Vibration Signal on Wire Bonder .

-

Integrated Circuit Packaging, Assembly and Interconnections

This includes not just the addition of necessary capitol equipment such as die bonders and wire bonders but putting in place complete die management procedures, covering storage, handling, inspections, and the assembly process.

-

Unconventional applications of wire bonding create opportunities for microsystem integration

The company initially supplied the US transducers for wire bonding to other vendors, and later built their own wire bonder .

-

http://www.scirp.org/journal/PaperDownload.aspx?DOI=10.4236/ib.2010.21003

A Systematic Framework of Equipment Maintenance and Service with Application to Wire Bonder .

-

Design of advanced ultrasonic transducers for welding devices

The new transducer is mounted on a wire bonder with a flange whose special geometry was calculated by means of FEM simulations.

Indicates content that may require registration and/or purchase.

Indicates content that may require registration and/or purchase.